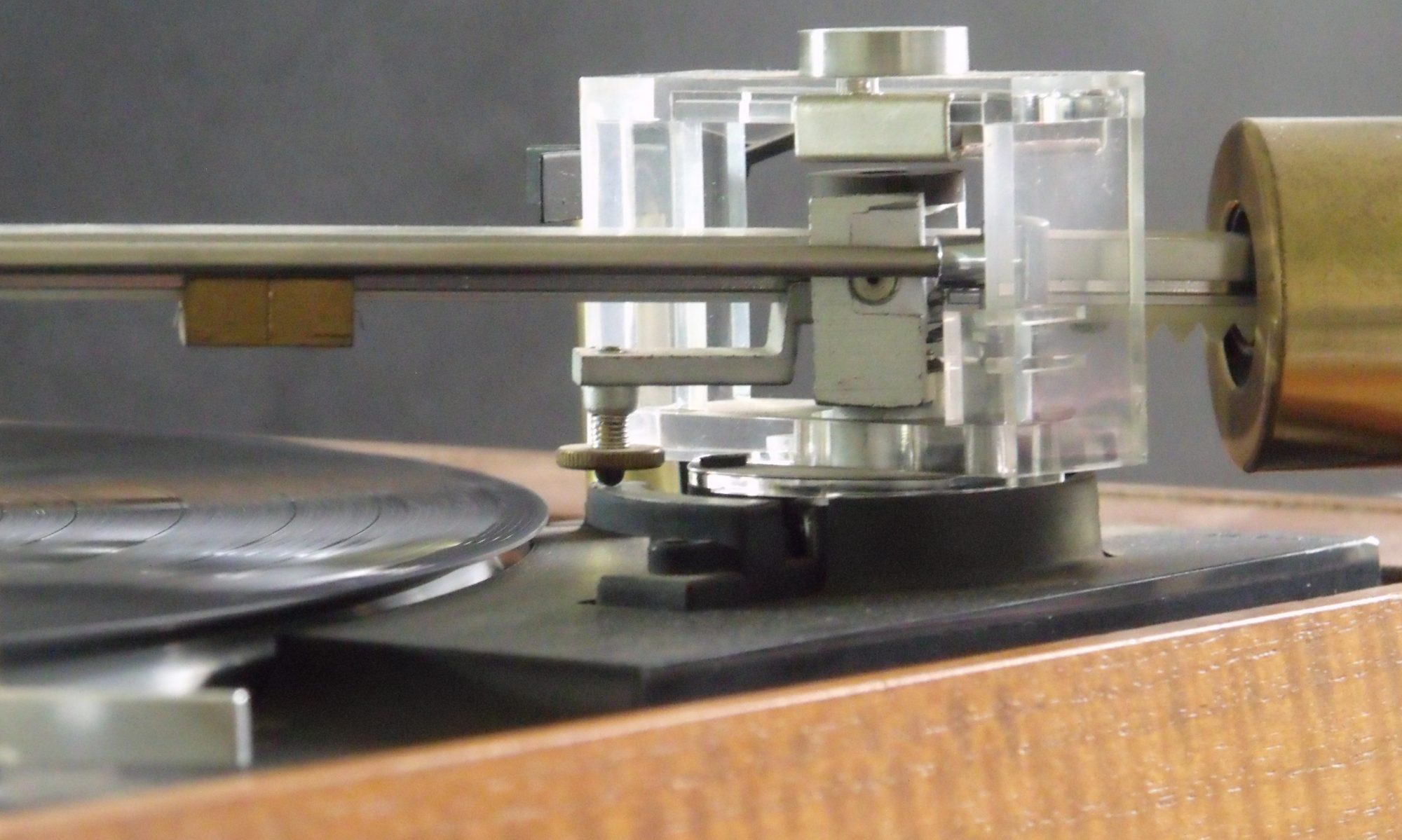

My turntable is a three point suspension type, so is quite well isolated anyway.

Every little helps though. No harm in trying to improve things, especially if it isn’t costing you anything.

My existing platform was simply made from a cheap wooden chopping board with isolation feet from double yellow dot squash balls. These were cut in half and affixed with hot glue from a gun. This had been in service for over a decade. How much difference it made to the sound I cannot really say. It did however reduce problems due to heavy feet on my wooden floor.

The new one is upping the ante somewhat. Squash balls again supply the isolation feet. However, this time they are located in stainless steel tube supports.

The platform itself is made from a kitchen worktop offcut made from a modern composite material. Silestone® is “a hybrid surface made from premium natural minerals and recycled materials. Manufactured with the exclusive and innovative HybriQ® technology, a more sustainable approach to architectural surfaces.” So there you go. It looks nice and is stiff and heavy. That’s good enough for my application.

The new platform weighs nearly 8Kg. Thats 2 1/2 times the 3.1Kg wooden platform it replaces. It will be interesting to see if it makes any difference to the sound. It certainly ups the specification and looks the business.

There is a lot to like about this. First the cost. Just £10 for the squash balls. The worktop was an offcut. It was also easy to make. I didn’t lift a finger. My Cousin Nik was making one for himself. Just as easy to make two as one. Reluctantly, I must give him full credit for a job well done.