I buy a lot of vinyl from charity shops and car boot sales. It often needs a good clean. Commercially available machines are good, but you don’t see much change from £500, so I built this.

Now the science bit. Wet cleaning records is a good idea, but the usual approach is to wipe on some sort of cleaning fluid, then wipe it off. The fluid hopefully dissolves the muck, which you then remove. Problem is that if you don’t remove the fluid before it dries you can actually make things worse. The fluid can carry surface dirt down into the grooves and deposit it as a sticky sludge where it does more harm. Commercial record cleaning machines (RCMs) use some sort of suction to remove the fluid by force before it dries. That way you get a very clean record.

My machine is a mixture of bits, largely acquired from car boot sales. I wouldn’t risk my best vinyl on this, that’s not the point. This is all about resurrecting dodgy second hand purchases, and it does that with aplomb! Let’s take a tour.

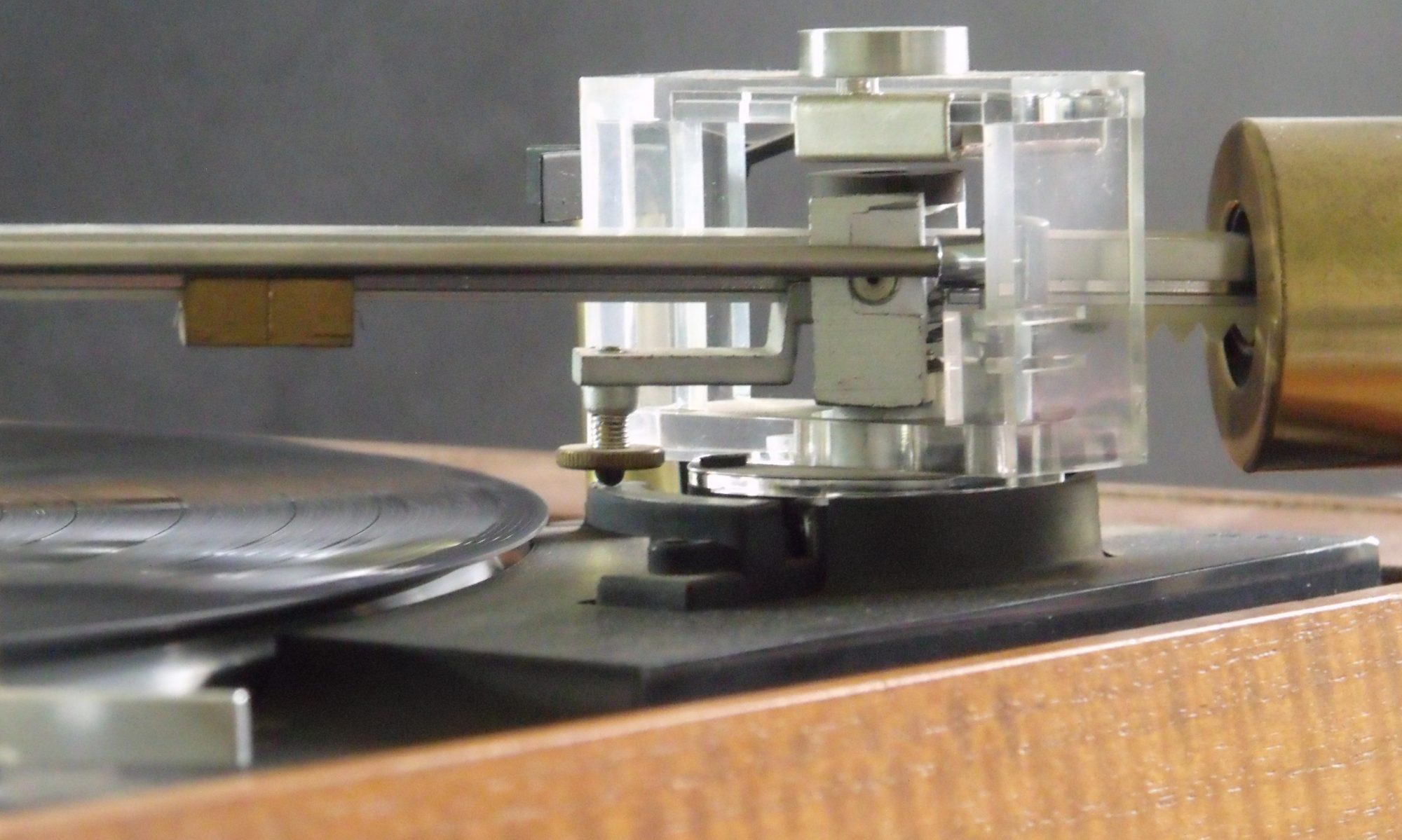

Contrary to popular belief, those horrible cheap record players that you can buy in supermarkets and certain high street record stores are not completely useless. I use one here as the mechanical base for my machine. The horrible stylus and cartridge has gone in the bin, where it can do no more harm. The arm is retained to support the suction head. The turntable will support and turn the record being cleaned. Most of the rest of the electronics have been removed, leaving just the battery and motor. That’s important. There is a lot of fluid sloshing about when in use, so keeping mains out of the way is an excellent idea .

The suction head is the business end of the machine. Mine is made of Teflon, otherwise known as PTFE. This is a hard slippery plastic used in none stick pans. Teflon is also used in the electronics trade to make the tips of solder removal tools. That’s handy, because a spare solder sucker tip costs less than a quid and makes a great suction head for my machine. I attached it to the end of the arm with a bit of twisted wire to try out the concept and it’s been that way since. If it ain’t broke…

In order for this whole thing to work I needed a quiet but powerful source of suction. This was actually the hardest part of the project. I had various false starts. These included converting aquarium pumps, various small vacuum cleaners, a windscreen washer pump and car tyre compressors. The pump I use is actually from a medical nebulizer machine. These are used to deliver air and drugs to a sleeping patient. No surprise that mine came from a boot sale. To make it suck, rather than blow, air I just swapped over the inlet and outlet pipes. The tubing used is ordinary aquarium air line.

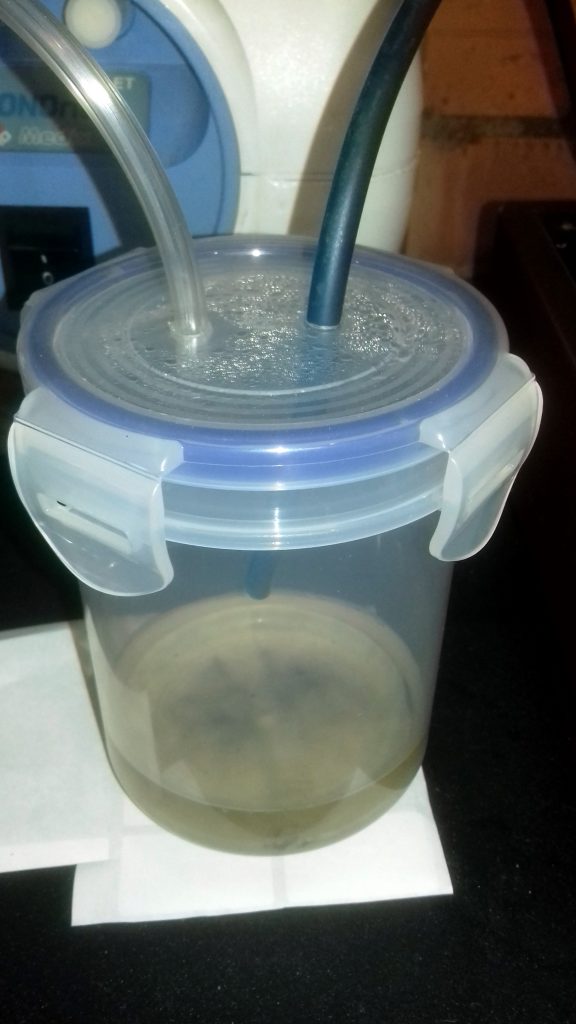

The fluid trap sits on the air line between the head and the pump. It’s purpose is to collect the cleaning fluid which is sucked from the record. Here you can see just how effective the cleaner is. That fluid is filthy. It is made from an air tight food container from a supermarket. The hoses are just a close push fit into a couple of holes in the lid.

The setup you see here was intended as just a prototype that I would build into a fancy case at some point. That isn’t going to happen because it works fine as it is and only takes a couple of minutes to do a record.

The name PlecRec is a concatenation of Plecostomus and Record. The Plecostomus, or “plec”, as they are known to fish keepers, are a breed of catfish which spend much of their time up against the glass of the aquarium sucking off any algae. A fitting analogy to how this machine works.