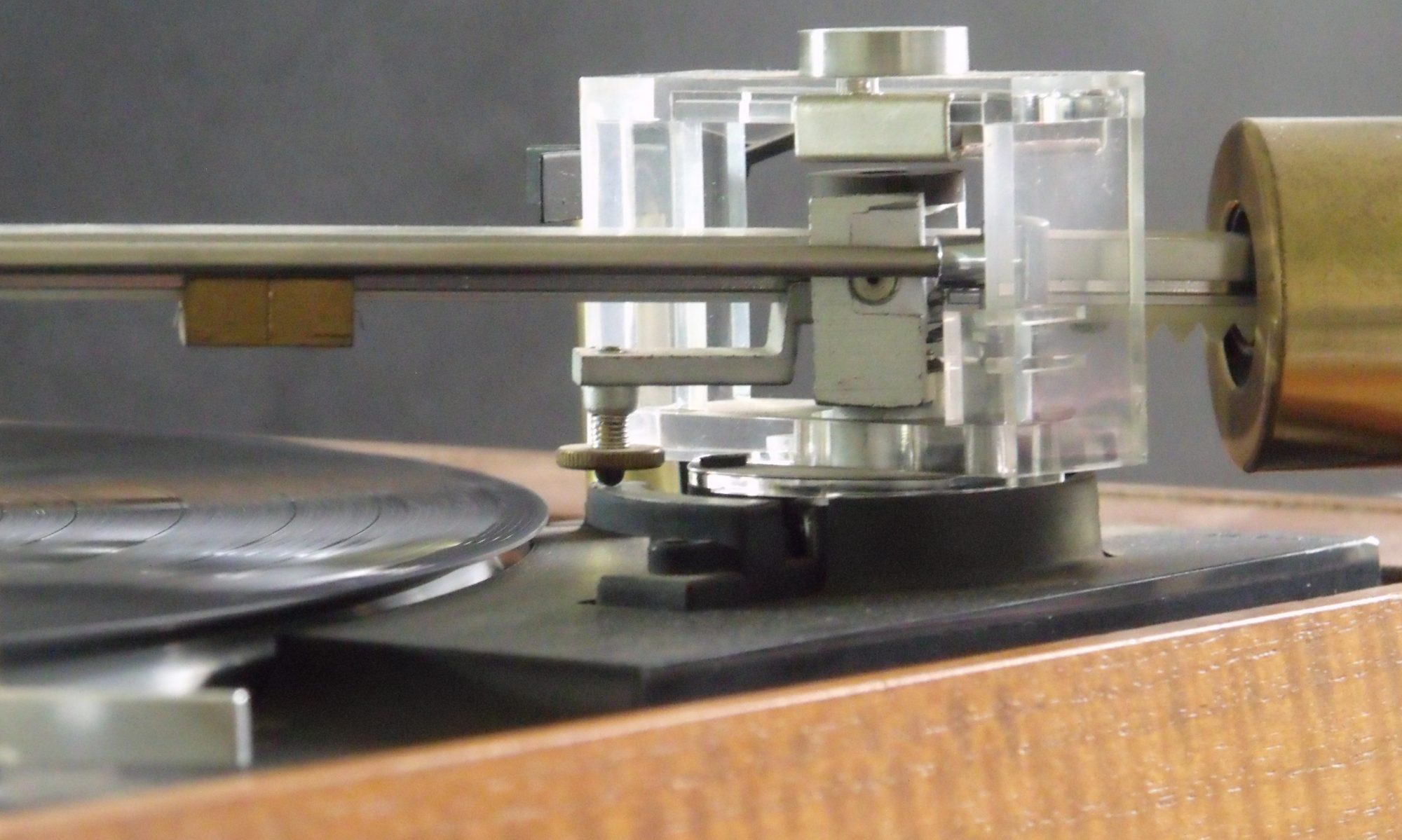

I bought this a few weeks ago for just £20. It didn’t work so I ordered new belts.

Time to fit them and see if anything else is wrong.

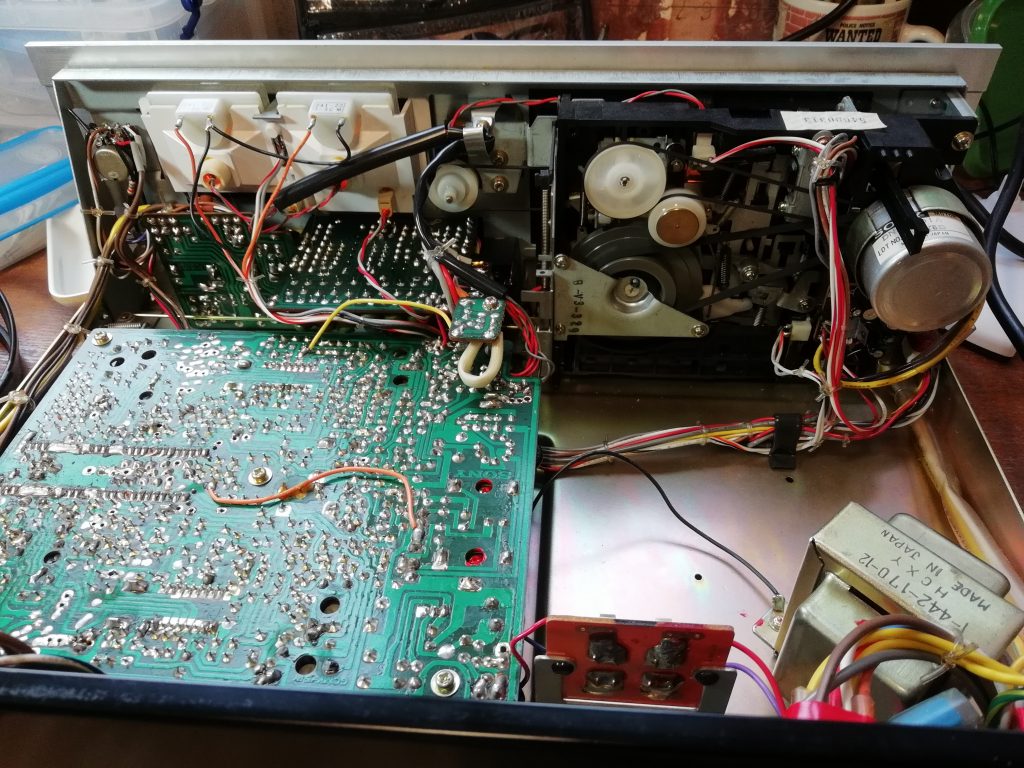

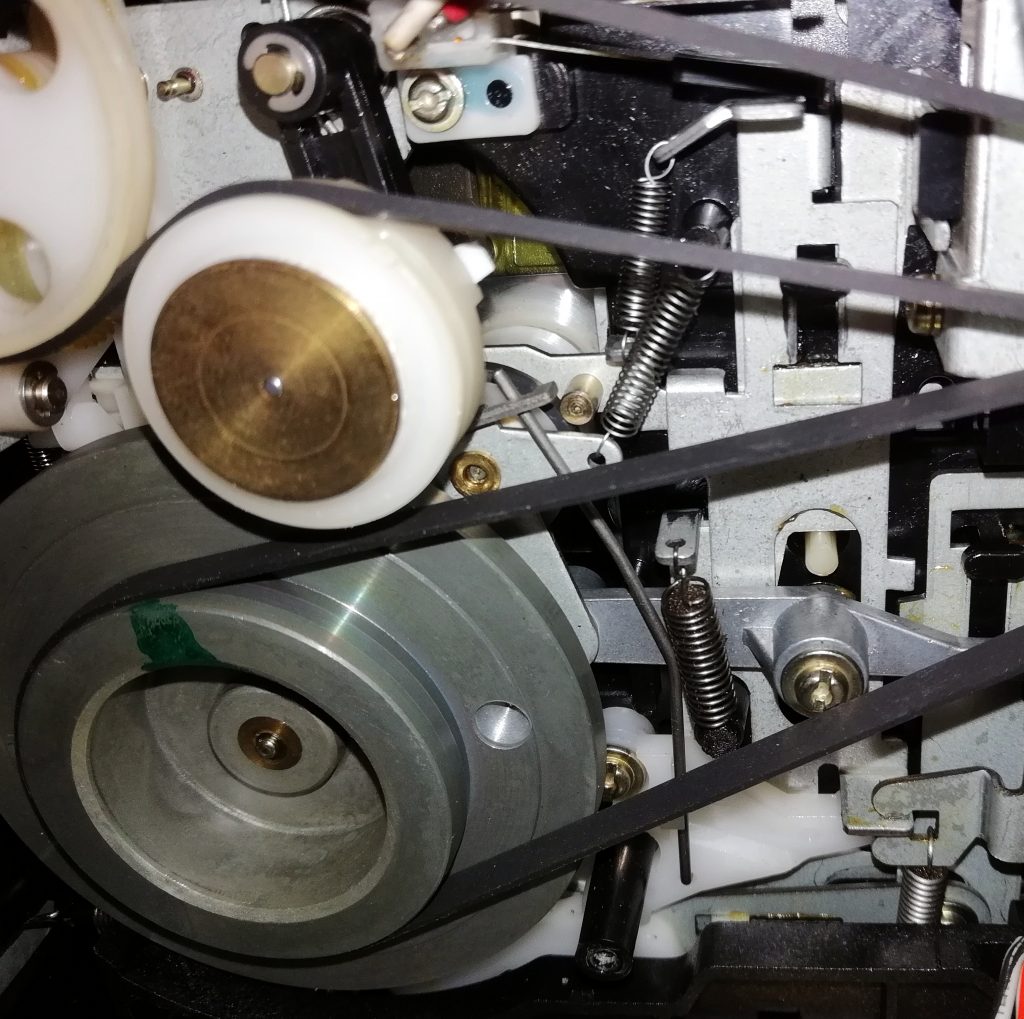

Inside all looks very clean and tidy, with the build quality of a chieftain tank.

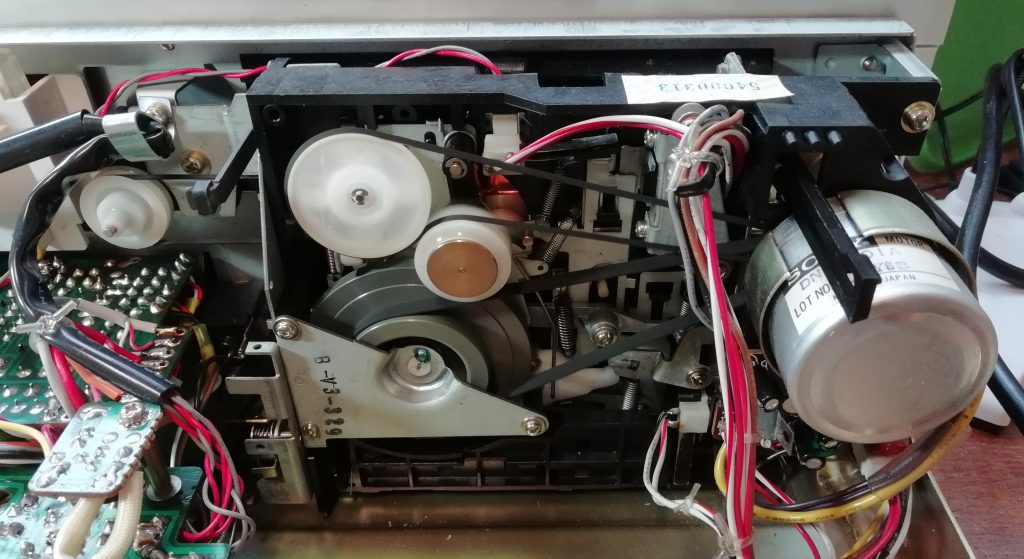

Three belts need fitting. The most difficult is the counter belt, which has to feed through the front of the unit in order to be fitted round the take up spool spigot, which has a built in pulley. This is impossible to photograph and fiddly to do. A head torch, tweezers, tenacity and a large swear box are your tools here. No further disassembly is required.

Two more belts come straight from the motor. The square section belt is easily fitted around two plastic pulleys. The larger flat section belt is the main drive to the flywheel and capstan.

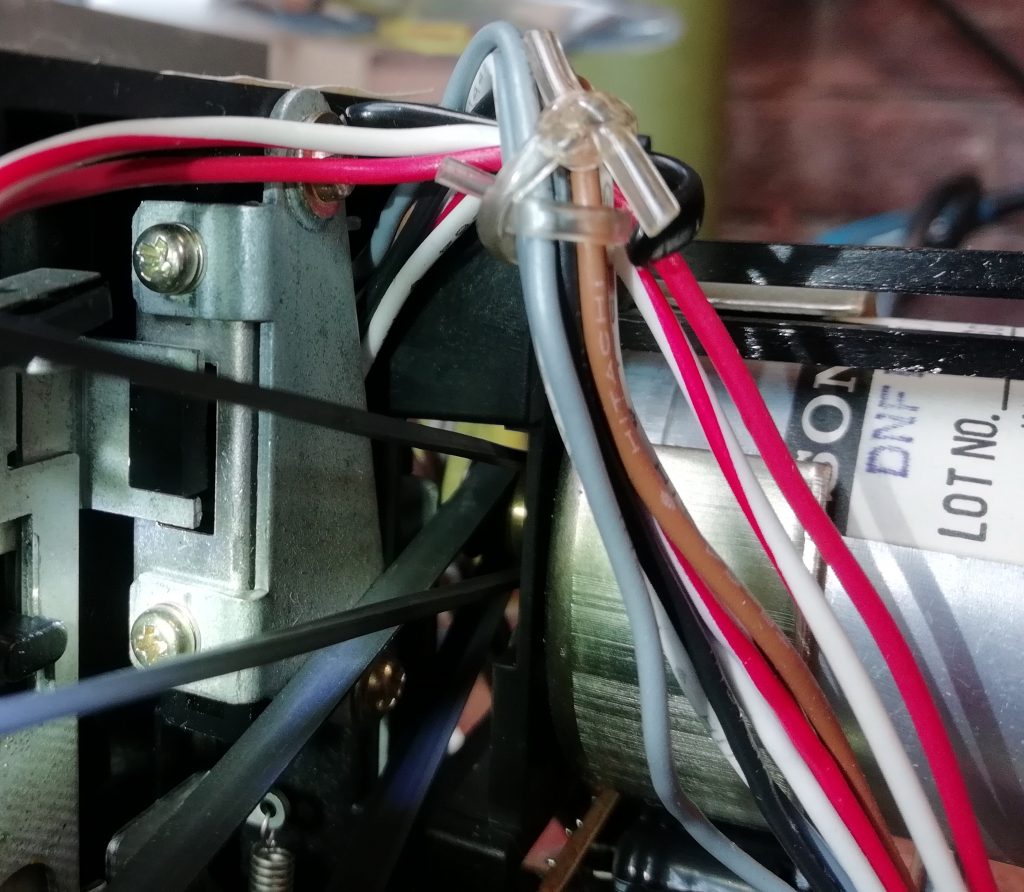

In order to get this belt round the flywheel, the back plate must be removed. Just 3 screws secure this. It is not necessary to remove the flywheel and capstan to change the belts, but I did, to lubricate and to take a few more photographs of the mechanism. Getting the pulleys onto the motor is another fiddly job, but then it all goes back together with ease.

Testing was done with some Chic, as you do. All functions seem to work and the sound quality is excellent. however something is still not right. At the start of Le Freak the “Aaaaaaaaa” went on for just a bit too long and the following “freak out” was delivered by what sounded like a rugby team. Hmm? Perhaps we are running a little slow.

I soon found the speed adjustment pot on a circuit board below the motor. At first I adjusted it by ear, which I can do quite well because I am fortunate to have pretty good pitch. However, we can probably do better with a more scientific approach .

The method prescribed in many service manuals for this is to use a test tape, which has a reference tone recorded on it, and feed the output into a frequency meter. Speed adjustment is then made until the expected frequency is measured. I don’t have such facilities, so some improvisation is in order.

I own a decent Yamaha cassette deck which is in good working order. I used this to record a 440 Hz test sine wave, via a computer sound card. This tape is obviously only as good as the calibration of the Yamaha. A compromise which I accept.

So to the calibration of the speed on the Sony. I used a chromatic instrument tuner for frequency measurement. The note A is defined as 440 Hz for the purpose of tuning instruments to “concert pitch”.

The tuner sits cradled in a pair of headphones, plugged into the deck. The test tape plays and the motor speed is adjusted until the tuner shows that the an “A” note is being played in tune.

The result is great. A short test recording was also successful, so I now declare this beautiful machine ready for active service.

To read about my first impressions, click here. Unfortunately my delight was short lived. The motor decided to seize up. Read all about how I fixed it here.