This one was acquired by a relative for a very good price. Cosmetically and mechanically it looks to be in excellent condition.

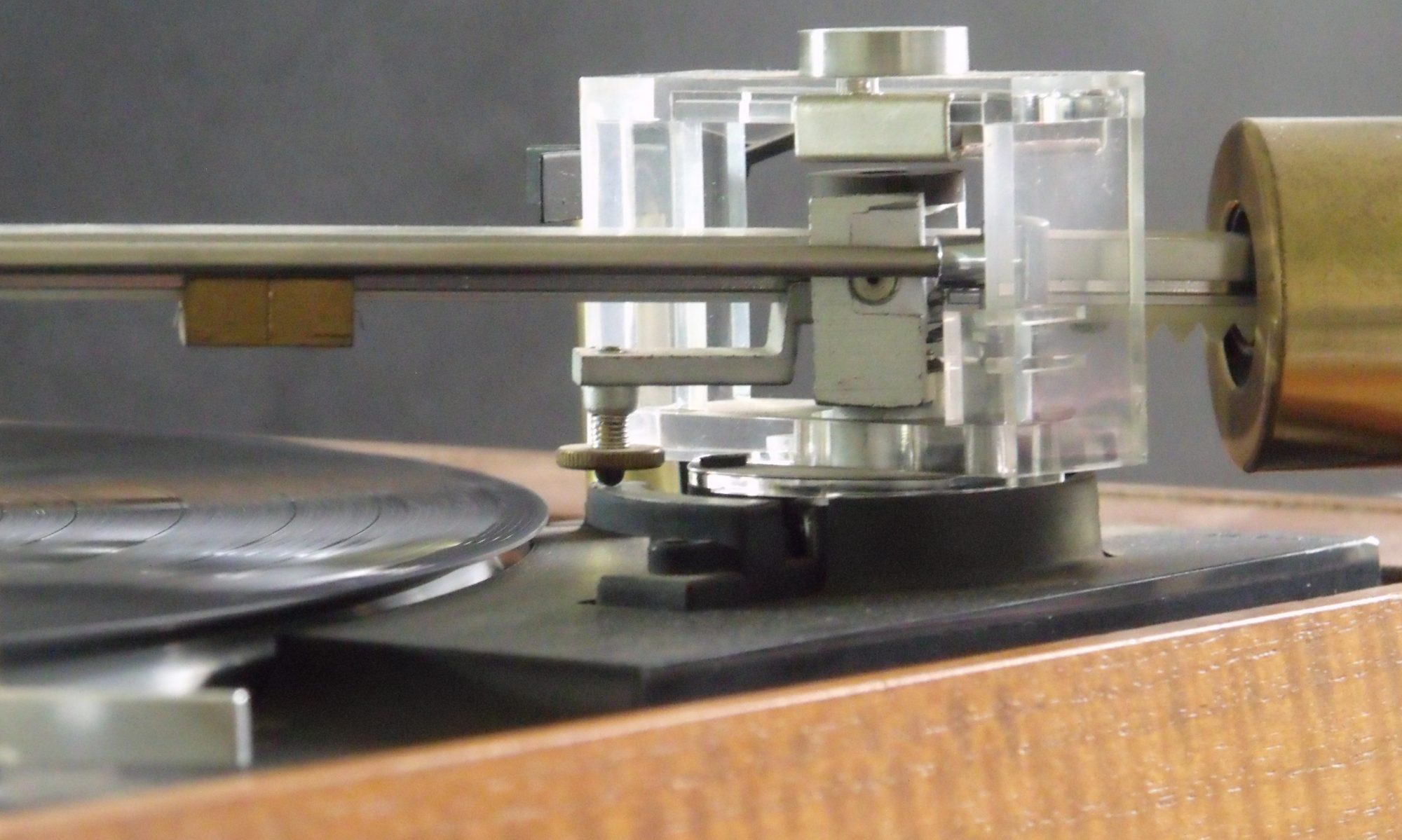

These turntables have a reputation for fantastic performance. It is a 3 point spring suspended design. Those columns house the springs. The arm is made from exotic alloys and is very well engineered.

Unfortunately it does not turn. The motor control is via high voltage circuits and some of the wiring looks propper dodgy. One to take care and precautions with.

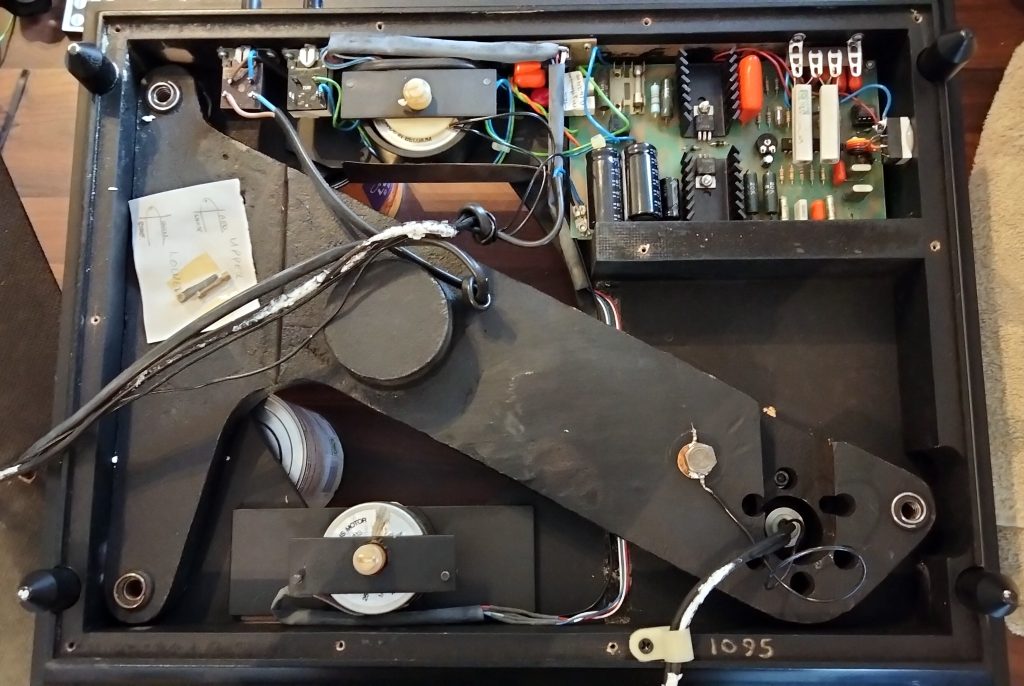

The suspended chassis is a very heavy metal casting, visible here in an under side view. It has two motors, visible top and bottom of this picture. These are AC Synchronous type and are driven from a quartz crystal locked power supply. Or they should be. That seems to be where the problem lies. Mechanically all seems to be in order. A new belt sits waiting for when the motor drive is fixed.

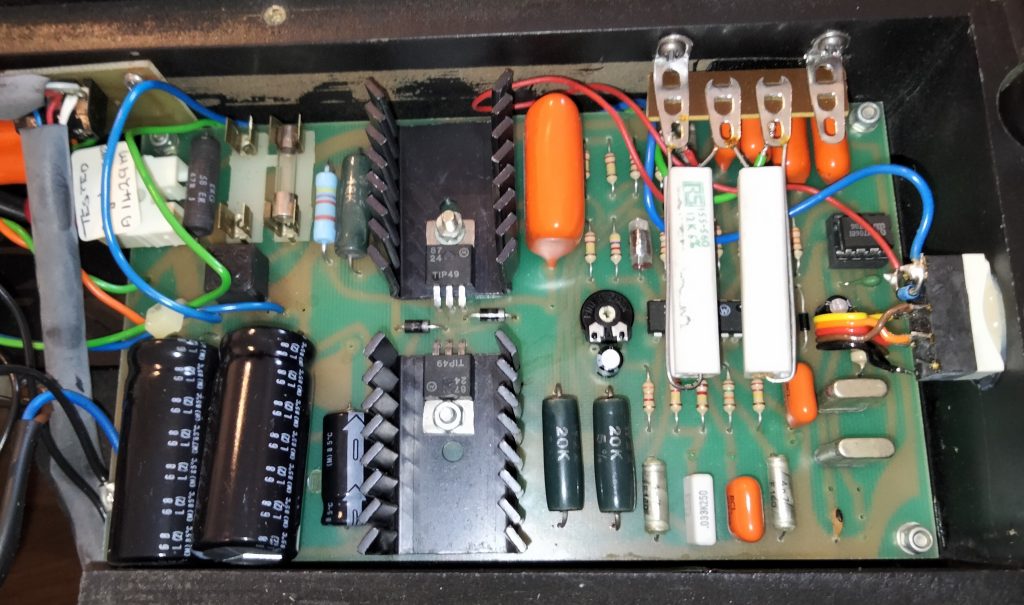

There is very little information available online for this deck, but I was able to get a user guide and circuit diagram from Vinyl Engine. The diagram did not match the boardas I found it. However, the various heath robinson modifications you see here do bring it close.

At one end of the board is the accurate frequency reference which is responsible for the tight regulation of the motor. The M706B 1integrated circuit at the top is a simple digital circuit which takes the natural oscillating frequency of the attached crystal and divides it down to give a solid stable 50Hz signal on pin 2. It also provides a 90 degree shifted verison of this signal on pin 3. Ideal for driving two coil synchronous motors like these. Shame the design doesn’t use it. I digress. We also need to be able to run at 45rpm. This needs the motors to be operated faster. A higher frequency is required for this. That’s why there are two crystals (top right) and a circuit to connect only the appropriate one. The relay at the top does this switching, controlled in turn by the 33/45 rpm selector button. The bloody great wire wound resistors on the tag board drop the voltage to drive the coil of the relay. The latter is glued to the plinth and connected by flying leads to the board. Not a great look for a premium turntable, is it. I do hope this was improved in the later version of the board.

The square wave coming out of the M706B1 is not suitablefor driving the motors. It would actually create a lot of interference which would likely be picked up by the cartridge. The next part of the circuit is mainly filtering to reduce this problem. The LM324 chip contains four op-amps. These are used with various resistors and capacitors to implement these filters and to drive the TIP49 power transistors.. With their heatsinks, these dominate the middle of the board and drive one of the coils of the motors. The other coil is driven via the large orange capacitor in the middle of the board. The capacitor provides the necessary phase shift. Nothing wrong with this approach. We often see “run capacitors” associated with synchronous motors. It is a shame though that they did not exploit pin 3 of the M706B1 to get a correctly timed signal. That would have required replicating much of the rest of the circuit though.

Having understood how the motor driver was supposed to work I fixed the obvious fault. That fuse was blown. The empty socket is supposed to be that way. Needed if you are running on 110V, apparently. So far, so good. Time to plug it in.

Maybe not. Yes there are two twin core cables going into that plug. A couple of single strands as well. No way I’m going to plug this in! Turns out that one of the twin’s in wired correctly. All the other wires go to the earth terminal. Back at the turntable these various earth connections are secured to random places. I think that the owner was experieencing mains hum problems and decided that loads of earth connections would solve it. Er. No. I removed them all. Sure enough I later found a lose earth connection on the tone arm wiring. That fixed the hum issue.

So here it is hooked up to a Cyrus based system for basic functional test. I temporarily fitted with a lowly Ortofon OM5E cartridge. It deserves much better, but this was enough to demonstrate that the arm wiring was ok and we had correct motor operation and speed.

My work here is done, but it’s owner will continue with mechanical set up and minor cosmetic work. It is a magnificent turntable. All the bits are there, including a perfect lid and the heavy “puck”.

Despite my reservations about the crude implementation of the motor control I was very impressed by this unit. I would love to own it. He’s not letting it go though …