Hiding in a dark corner of a local antiques centre was this chunk of fine German Engineering.

The label declared that it was “running slow”. For just £35 it would be rude not to find out just how slow.

The case in excellent condition and more that worth the whole purchase price, even if that’s all I end up using; perhaps to house an alternative dual like a 505.

The plinth is in fine condition, with no scratches or chips. but the real value of the case lies in the immaculate perspex lid. These are sometimes badly scratched or cracked, often where they meet the hinge. Perspex is very difficult to repair, as discussed here.

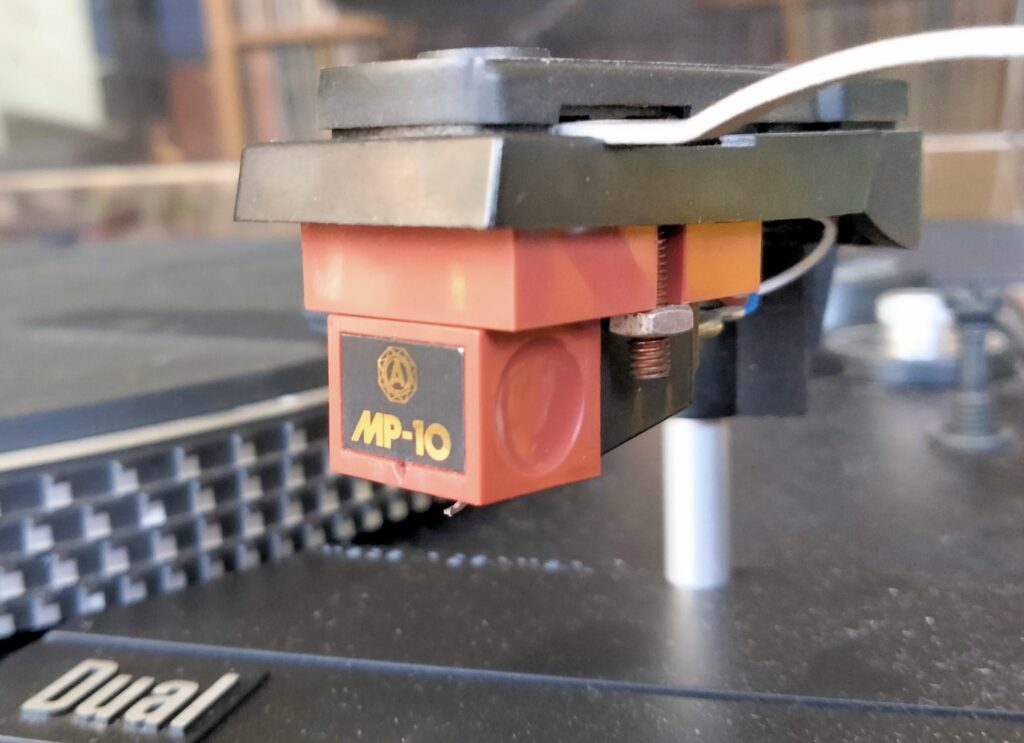

A rather nice Nagaoka MP-10 cartridge is fitted. This is a worthy upgrade from the original cartridge which suggests a level of knowledge and appreciation on the part of the previous owner. Sadly, on closer inspection at home, I discovered that the stylus has lost it’s tip. I expect this was a casualty of rought handling in the antique centre.

Besides the damaged stylus, all is present and correct. There are no cosmetic blemishes. The lid opens silently. The Platter rotates by hand and the arm moves smoothly in all planes. Moving the arm from rest starts the motor but the platter barely moves. As I expected, the slow speed is down to a stretched drive belt. The description did say it runs slow and belts are a consumable component, so no surprises here.

The 504, from 1977, pre dates the popular 505ii by half a dozen years. Many of the features which made it’s successor so popular are already in place. The 504 is a fine turntable in it’s own right. I’ve seen enough to know that, despite only buying it for the case, this one is worth the investment of a few quid to get it working. A new belt and a drop of oil on the main bearing restored platter rotation, but speed is still not right.

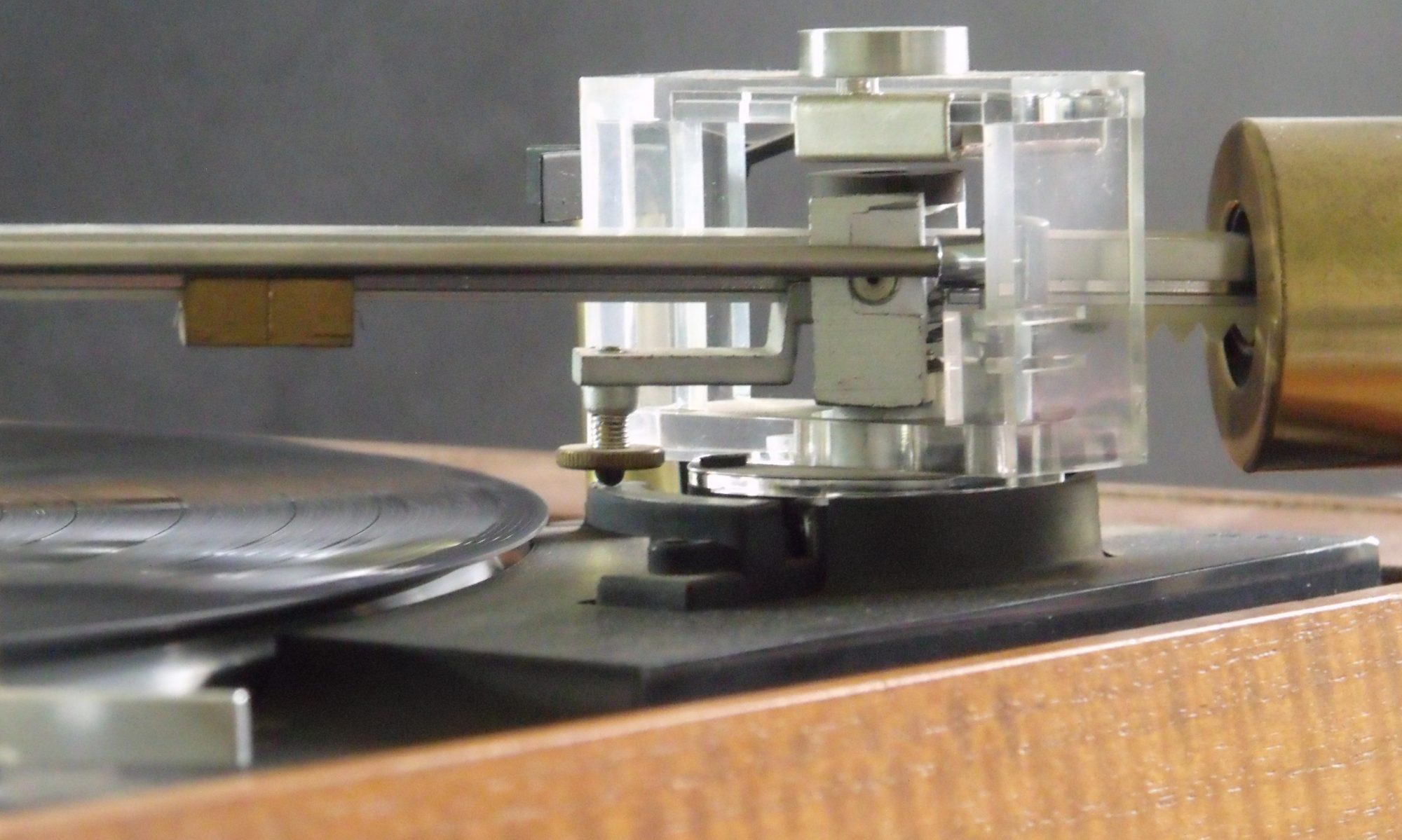

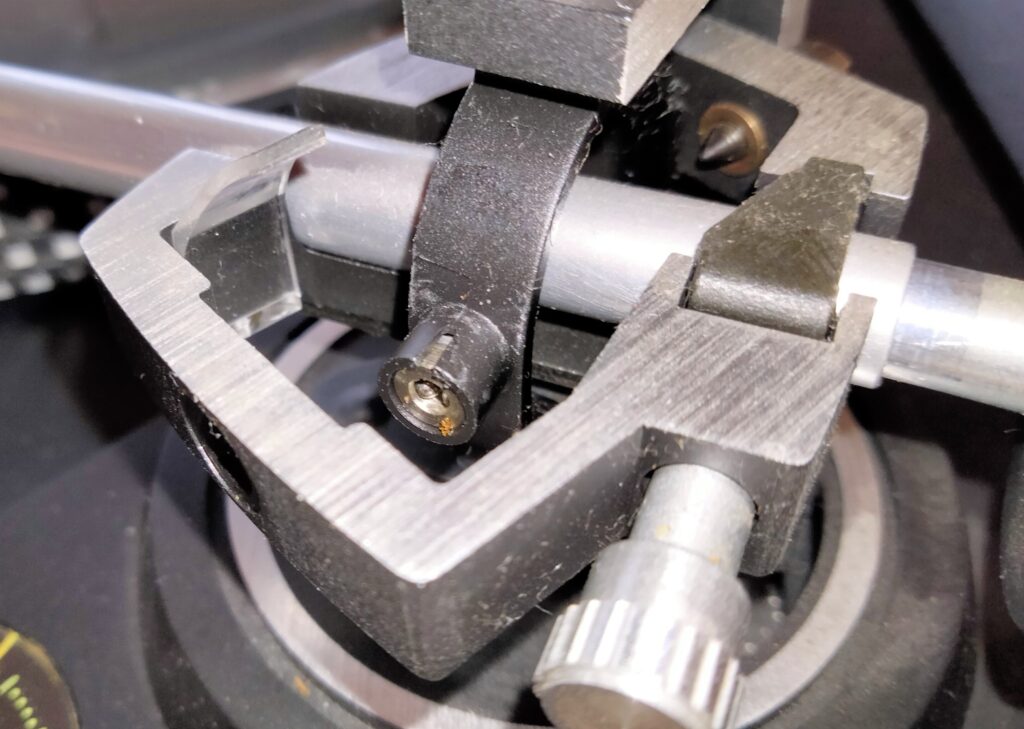

The 504 has the “Vario Pulley” pitch control mechanism. A splined motor pulley is expanded by a tapered pin to change its effective external diameter, and hence change the speed. On this machine the pitch mechanism is filthy and siezed solid.

I took the whole mechanism apart, cleaned it up with IPA on a cotton swab and re assembled with fresh lubricant.

Here you see how pressing down on the tapered pin expands the Vario Pulley to change its diameter. I was able to get the platter running at 33 rpm by adjusting the “nominal speed nut” with a spanner.

A toothed belt should connect this mechanism to an external adjustment knob (alieviating the need for a spanner) Sadly, but not surprisingly, this belt has stretched and its teeth don’t mesh with the gears as required. A replacement for this rare part would be difficult and expensive to source.

Boiling an old belt sometimes helps, but not today. My pragmatic fix was to put a cable tie around the belt to tighten it onto the cogs. Not pretty, and not one you could use for any sort of drive belt. However, here it works. It’s a none destructive botch and a future owner may want to sell a kidney and fit a replacement belt instead.

The sadly damaged Nagaoka MP-10 was temporarily replaced with a cheap Audio Technica AT-91. The 504 mounts it’s cartridge on a removable pick up head so this was a straightforward excercise. Following the documented procedure for setup and adjustment went well until I tried to turn the tracking force to 2g The dial was not moving above 1.5g.

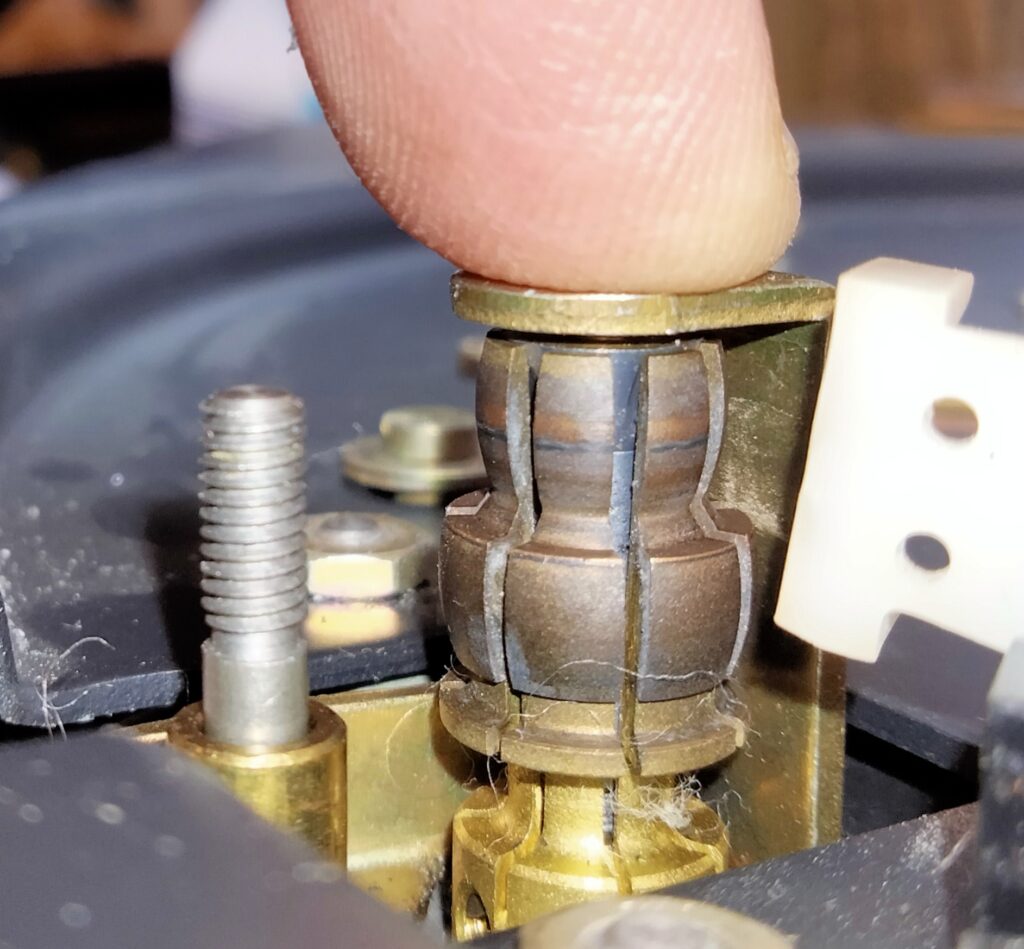

Study of service manuals for various Dual turntables, Google and YouTube did not help with understanding this problem. I did learn that the gimbal bearing used balls. The latter filled me with fear of dismantling the gimbal, lest they should make an escape bid and be lost forever.

I slept on the problem and reminded myself how little I had paid for the deck. Courage restored I took the gimbal apart. My fears about the balls were groundless. They were actually secured by a brass collar and were going nowhere. I could now remove the tracking force knob.

Tracking force is excerted by a tempered flat wound spring which applies force around the vertical pivot. This is contined inside the adjustment knob.

Looking at the other side of the assembly the problem was clear. The plastic knob has a metal threaded bush with a limit stop lug on it. I just needed to turn the bush round to the right place and then re assemble the whole gimbal assembly. It was then straightorward to set the required tracking force and confirm with an electronic gauge.

The last job was replacing the worn and tarnished phono plugs. It is now installed on my Bang & Olufsen Beomaster system. It worked a treat looks great and sounded fine.

A couple of months later I came by a Shure M75ED cartridge. This is a fine, period correct, elliptical stylus cartridge which is in excellent condition. It’s now fitted to this turntable and it sounds great. The change really did make a big difference to the sound and brings out the potential of this great vintage turntable.