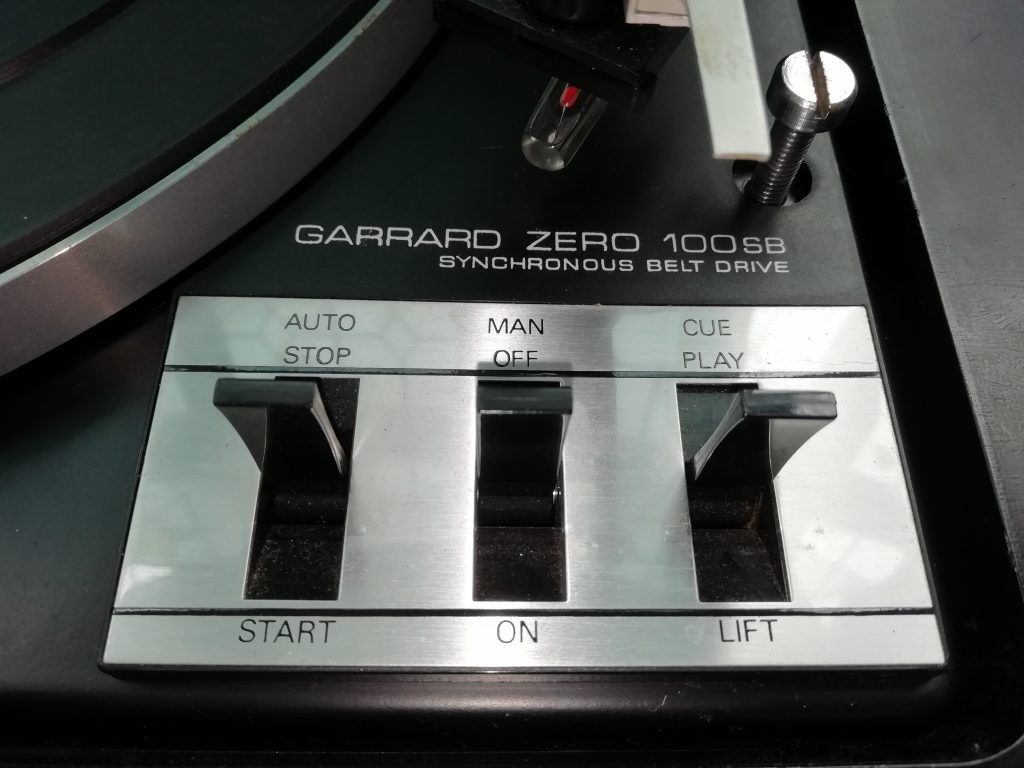

This recently purchased classic 1970’s British turntable was, for the most part, in excellent condition.

However it was described as “faulty”, which indeed it is. So let’s fix it.

This time I’m going to start with cosmetic issues. I normally delay such work until I have the mechanics sorted. This is mainly so that I don’t damage a nicely repaired case during other repairs. Sometimes mechanical repair isn’t possible, so why waste time on cosmetics. My first impressions of this turntable were excellent, so no this occasion I am confident confident the mechanics will be repairable. The deck needs to come out of the plinth for repair anyway, so cosmetic and mechanical repairs can commence concurrently. This will also give the paint plenty of time to dry before re-uniting the deck and plinth.

Here we see the damage to the plinth. An anti static brush had been crudely glued to the top left hand corner. I failed to cleanly remove this, leaving glue residue and scratched paint. There is also paint damage at the front.

Efforts to remove the aluminium surround were fruitless. I had hoped it could clip off, but it seems it is glued together pretty tight. I must be missing something. Is there a knack to this that I haven’t got? I decided to cut my losses and resort to careful application of masking tape to protect it.

Warhammer Chaos Black aerosol paint is again my weapon of choice. I used it previously on my dual 505 plinth project. This paint gives great coverage, sticks to anything, and provides a very pleasing satin black finish with just a couple of coats.

Here we see the damaged area after sanding down with wet & dry paper. It only took about 10 minutes.

After some more sanding, a couple of coats of paint and removing the masking tape we have this.

Moving on to the deck itself. A new belt was required, as expected. I was then able to actually play records straight away. The motor turned quietly and at the right speed. Audio connections were fine. Full stereo reproduction was present and correct. Very good it sounded as well. Arm lift worked smoothly. Manual on off switch was fine too. Any sort of automation was conspicuous by it’s absence. The arm didn’t raise or return at the end of play. The motor just kept running. Again this was consistent with the sellers description.

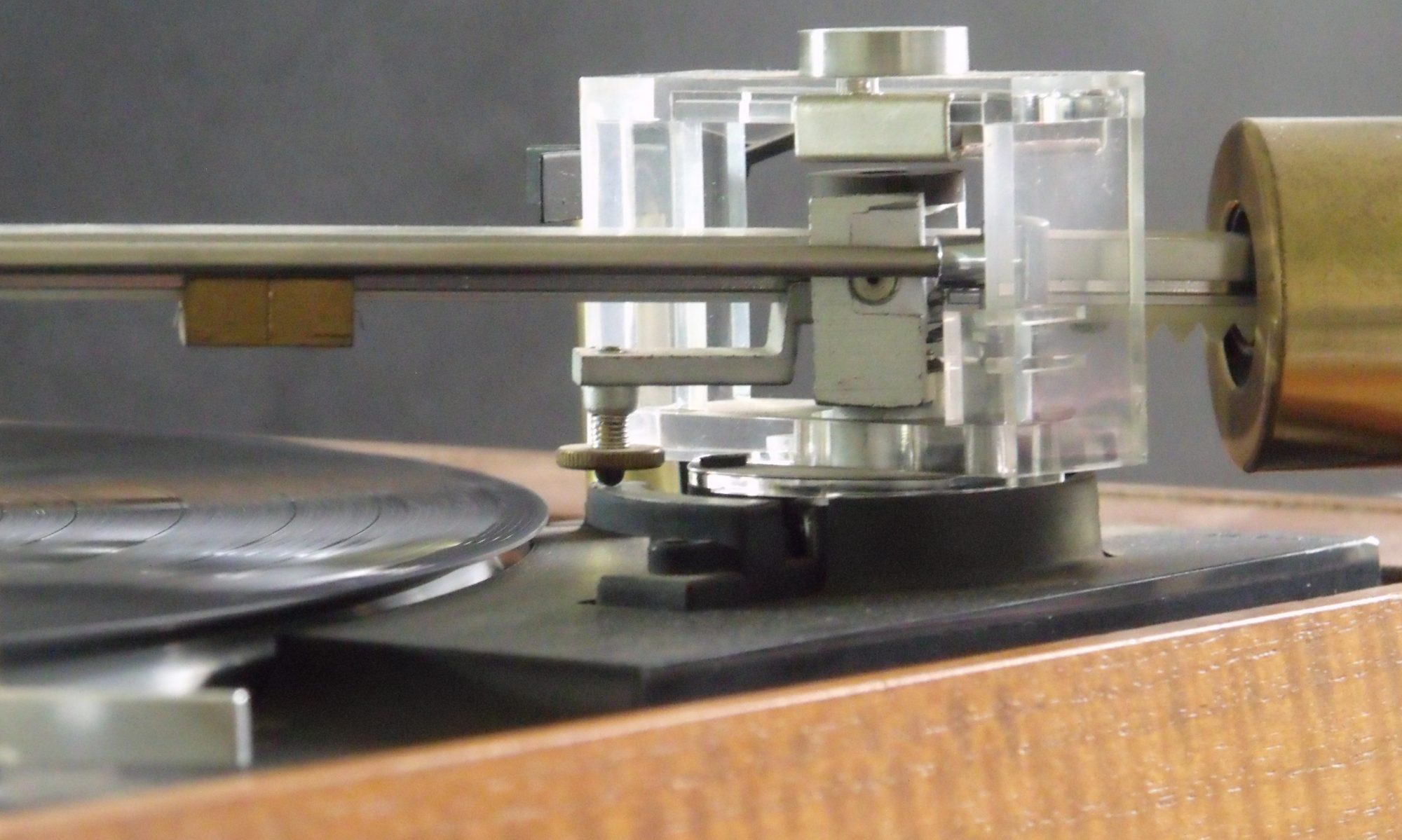

A look underneath revealed this rather bent and mangled component. It’s called a “trip pawl” and is an essential part of the automation mechanism. When any sort of automation is required this pawl is moved so that an extrusion on the platter catches on it and pushes the big gear above round by a few degrees. That engages the drive from the platter to the automation mechanism and the magic dance commences.

Looking from the top, after manually rotating the main drive cog, you can see the damage. More important, you can see the circlip that holds it in place.

I was able to remove the damaged pawl from the top without recourse to totally dismantling the mechanism underneath. On the bench it is clear that it is rather bent and distorted. It’s clearly not going to work.

Careful attention with pliers, a vice and a rather large hammer straightened the pawl. I re fitted it through the spindle hole on the top of the deck, lined everything up and managed to get the circlip back on without losing it. Now the automatic return and switch off at the end of a side worked. Progress. The auto switch still does nothing though.

As expected, this was caused by sticky grease on the multitude of links which make up the automatic mechanism. The only answer is meticulous cleaning off of old grease and re-lubrication.

At this point I have a turntable which auto start and stops. All is going well. Then I dropped it. Oh dear. It’s not well. Strange noises are coming from the motor and speed is rather slow and wobbly.

To be continued .. here