This was given to me by a friend. A “small problem with the arm” he said.

I’ve never been inside a direct drive turntable before. This will be interesting.

The problem presenting was that the arm would not lower when the cue control was operated. This turntable is semi automatic. At the end of play, or when the stop button is pressed, the arm lifts from the record and returns to it’s rest position. This adds complexity to the mechanism. The only way to find out where the problem lies is to go inside.

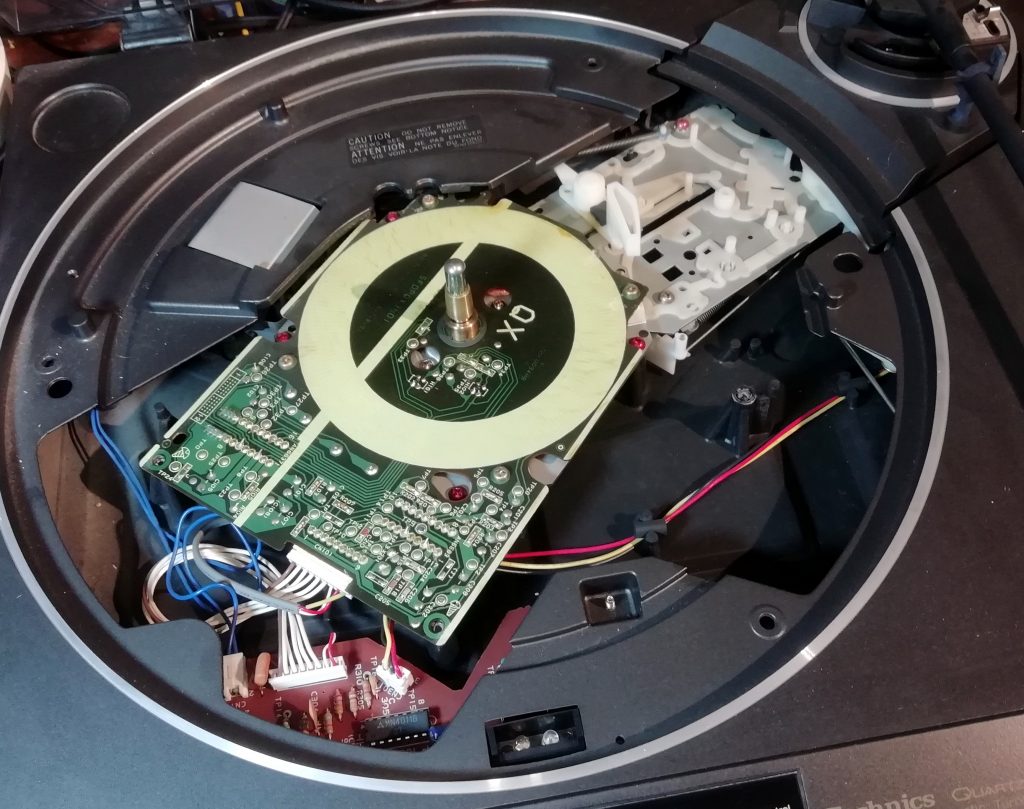

The first thing to remove is the turntable platter, which just lifts off after removing the rubber slip matt. Here we see the under side. The strobe markings around the outside are illuminated by LED strobe lights and visible through the front of the appliance via an internal mirror. Conspicuous by their absence are any means of connecting a motor drive to the platter. There is no drive belt or idler wheel as you would expect. What we do have is the large circular magnet, about four inches across, in the middle of the platter.

Under the platter is a cover which is easily removed to reveal some electronics and mechanics. There is no motor to be seen. Well, actually if you know what you are looking for the motor is there in clear sight. Well, half of it is.

Electric Motor 101. Electric motors work by creating a changing electric current in a set of coils of wire. A current in a wire creates magnetism. If the current is changing, so will the strength and direction of the magnetic field produced. If the coils are arranged in a circle and the timing of changes to the drive current are right, you get a rotating magnetic field. Magnets attract (or repel) each other. So, if magnets are brought near to the rotating magnetic field we have created with our coils, the magnets will rotate. In a regular DC motor the magnets and coils are contained in a can and the rotation is taken to the mechanism via a pulley and belt. An example of this can be seen in my motor service for a Sony Cassette deck.

This green circle is actually a set of coils made by the copper track pattern on the circuit board. When the platter is in place the big magnet sits up close and personal to these coils. The complex electronics we see on the rest of this circuit board are responsible for creating changing current in these coils. The electronics can very accurately control the timing of the changes. This is why direct drive turntables have excellent speed control and correspondingly magnificent wow and flutter specs. The reason we can find no motor in this turntable is because most of the turntable actually is the motor! A “direct drive” motor.

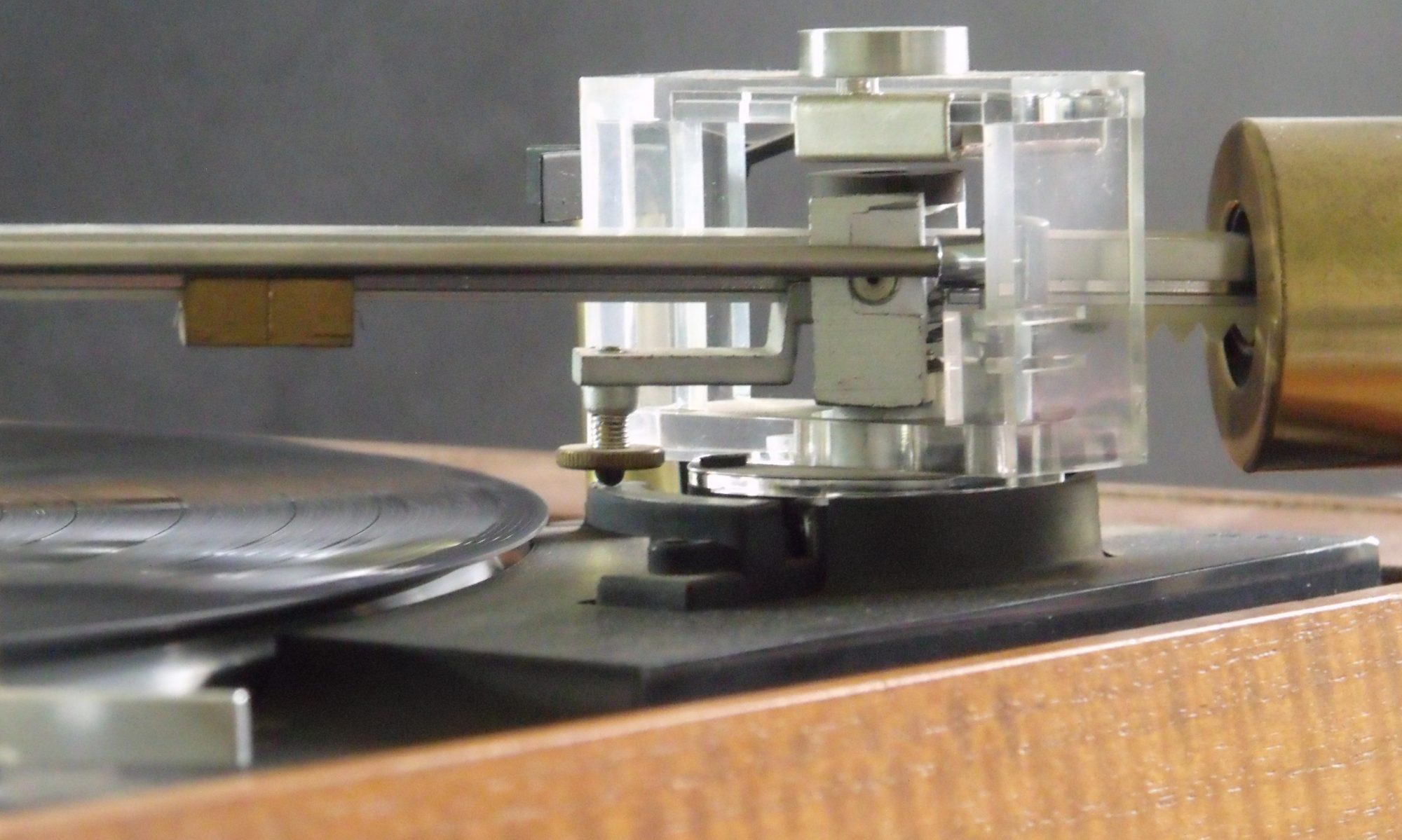

Back to the repair. The problem is with the tone arm. It is held in place by just a few screws, but I needed to separate the base from the turntable to gain access. As is often the case this was a straightforward but long process. the service manual from the excellent Vinyl Engine website and lots of photographs taken along the way were valuable here.

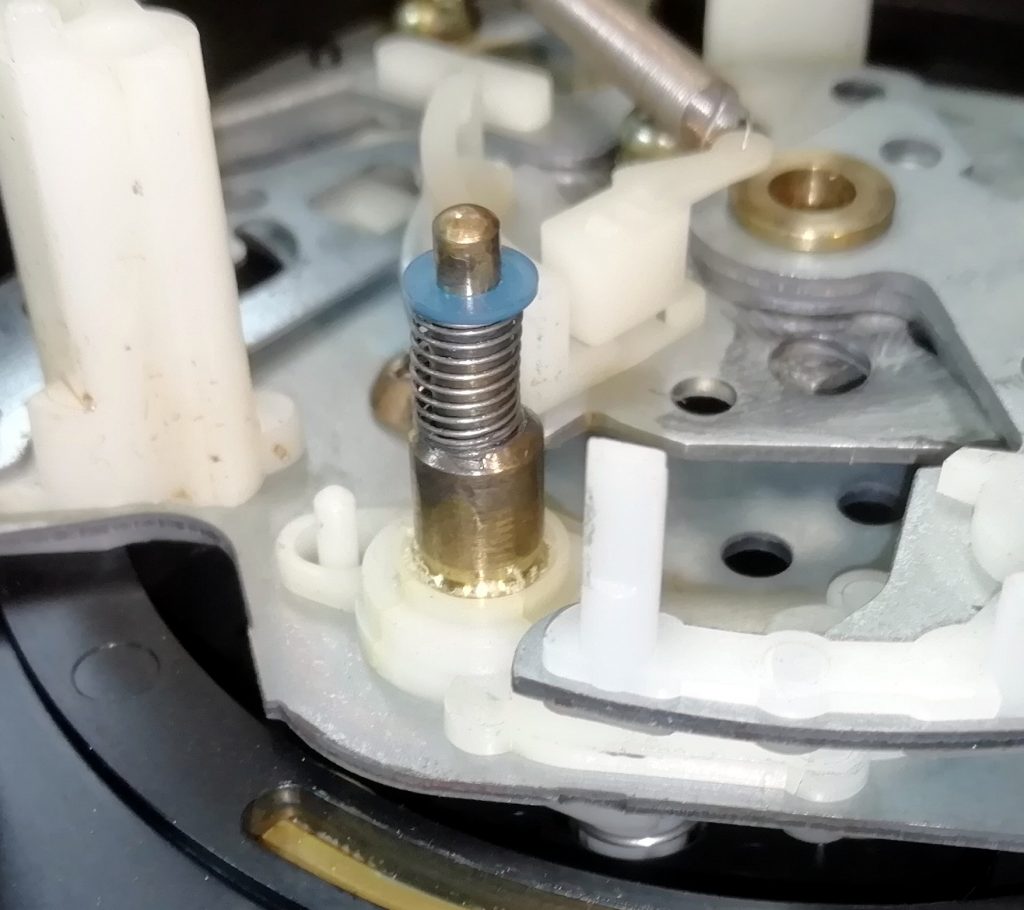

Turning it upside down I soon found the problem. The spring in the middle of this picture is the culprit. It is supposed to pull the arm lift down when the cue mechanism is released. It was seized solid and going nowhere. Isopropyl alcohol (IPA) was applied liberally over a couple of days to dissolve and flush out the old dried out lubricant before oiling afresh.

Re assembly was fiddly but straight forward. The mechanism worked smoothly straight away and required only minor adjustments.

The main adjustment made was the height the stylus raised off the record. I like this to be very small to aid accurate cuing. The stylus on this is, I’m assured, low mileage. No need to change it then. If I did it would cost about £30. Another interesting feature of this deck is the use of a P-mount cartridge. This standard was briefly popular as an alternative to the industry standard 1/2 in spaced bolts. All P-mount cartridges weight the same, track at the same force and comply to common physical dimensions. This makes it easy to change cartridges without having to concern yourself with compatibility issues or engage in lengthy set up procedures. I’m considering getting an Audio-Technica AT85EP for it. This is one of only a few P-mount cartridges currently in production. At only £5 more than a stylus alone it offers a considerable upgrade with an elliptical stylus rather than the original conical.

Despite all the high tech inside this repair turned out to be like so many others. Dried out lubricant, complicated by difficult access

I now fully appreciate why direct drive turntables are popular. The Technics SL-1200 is the famous big brother to this turntable. It uses more substantial coils and so is able to provide serious torque. It can start and stop very quickly. The speed control slider is larger and positioned on the top of the deck. The SL-1200 is, and always has been, very popular with DJ’s because of these features. The rock solid speed stability makes these popular in the HiFi world as well. the arm is often replaced with an SME fitted with a less robust, but better sounding cartridge.